MATTRIS'25 by A3TS: a record-breaking event focusing on innovation and the energy challenges of the future

Held from July 2 to 4 at the Parc des Expositions et des Congrès in Dijon, the Mattris '25 by A3TS trade show and conference confirmed its status as a benchmark event in the field of heat treatment and surface engineering.

Over 1,000 participants from companies, technology centers and research laboratories in some 15 countries came together to discuss the latest innovations in the treatment of metallic materials. A large number of students and recent graduates were also present.

On the program:

75 high-level conferences in French and English with subtitles, led by experts from the four corners of the globe.

250 national and international delegates

80 exhibitors from industry, research centers and universities

600 qualified visitors converged on Dijon.

The show also hosted a number of unifying initiatives:

two expert roundtables, one on the theme of theCircular Economy & recyclability of materials: what's at stake for heat and surface treatments? and the other on Materials for the Energies of the Future.

targeted BtoB meetings,

A3TS Innovation Competition,

photo competition on the theme of materials processing under the microscope,

the UITS Young People's Awards,

the presentation of thesis prizes in Heat Treatment and Surface Treatment,

job dating.

A program of visits to emblematic sites in the region was proposed:

Framatome 's Saint-Marcel and Montbard sites,

the Forges de Courcelles site in Nogent,

the UTT platform in Nogent,

the Calhipso platform in Dijon,

the Amphenol FCI and Aalberts sites in Besançon,

Smart Energy, a hydrogen production and distribution station in Dijon.

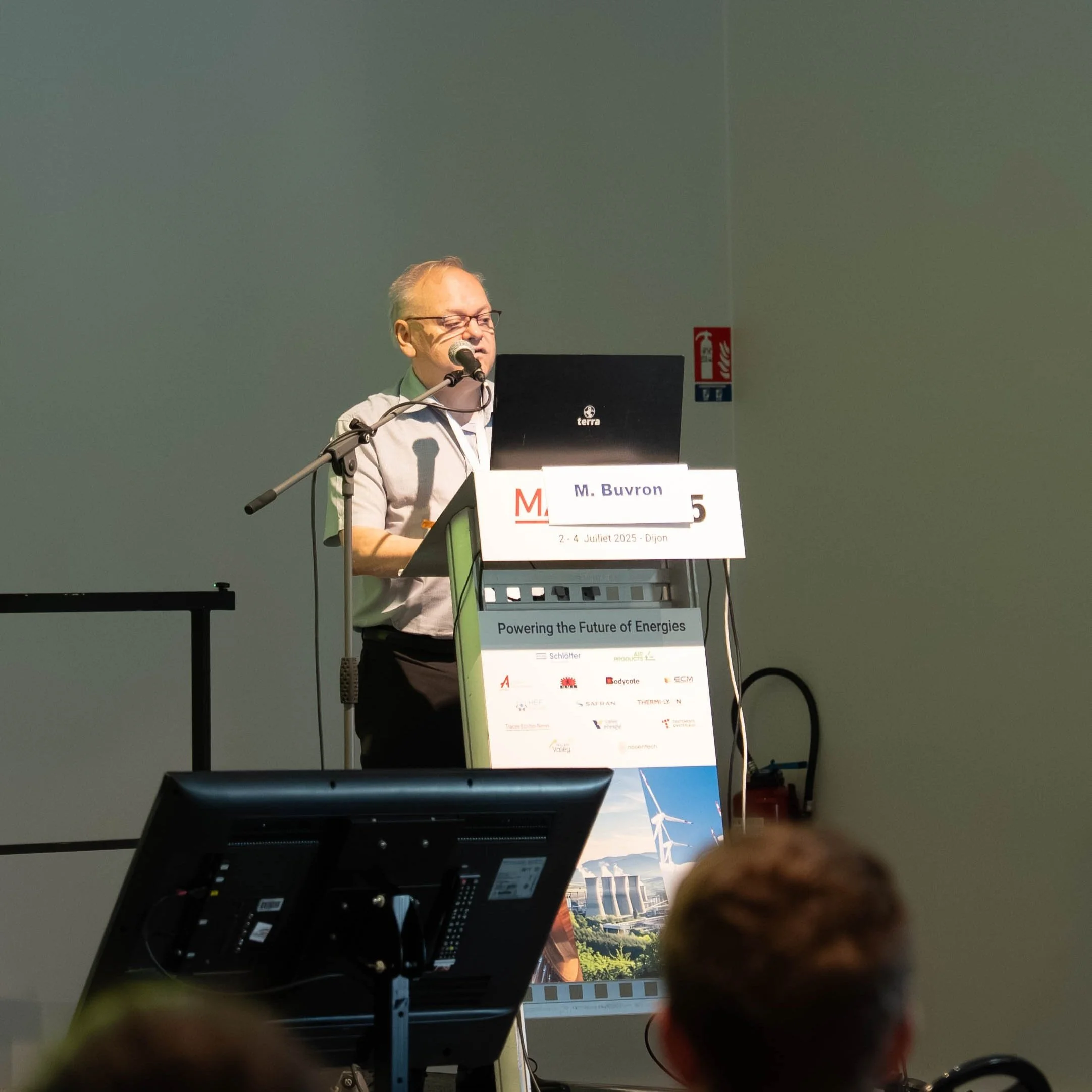

The plenary conferences

A vision of materials and manufacturing for the nuclear industry of tomorrow

Jean DHERS, Head of Materials - NEWCLEO

Innovative and sustainable steels for nuclear application

Nathalie PAUZE, Nuclear Head of Sales - INDUSTEEL

High-temperature treatments in powder metallurgy (MIM process). Objectives and differences from traditional heat treatments. Modeling and impact on chemistry.

Jean Claude BIHR, CEO - Doctor in metallurgy and French industry - ALLIANCE MIM

Alloys electrodeposition: the basis, the trends, the future

Jean-Yves HIHN, Head of Sonochemistry and Surface Reactivity Group - Université Marie et Louis Pasteur, CNRS UTINAM

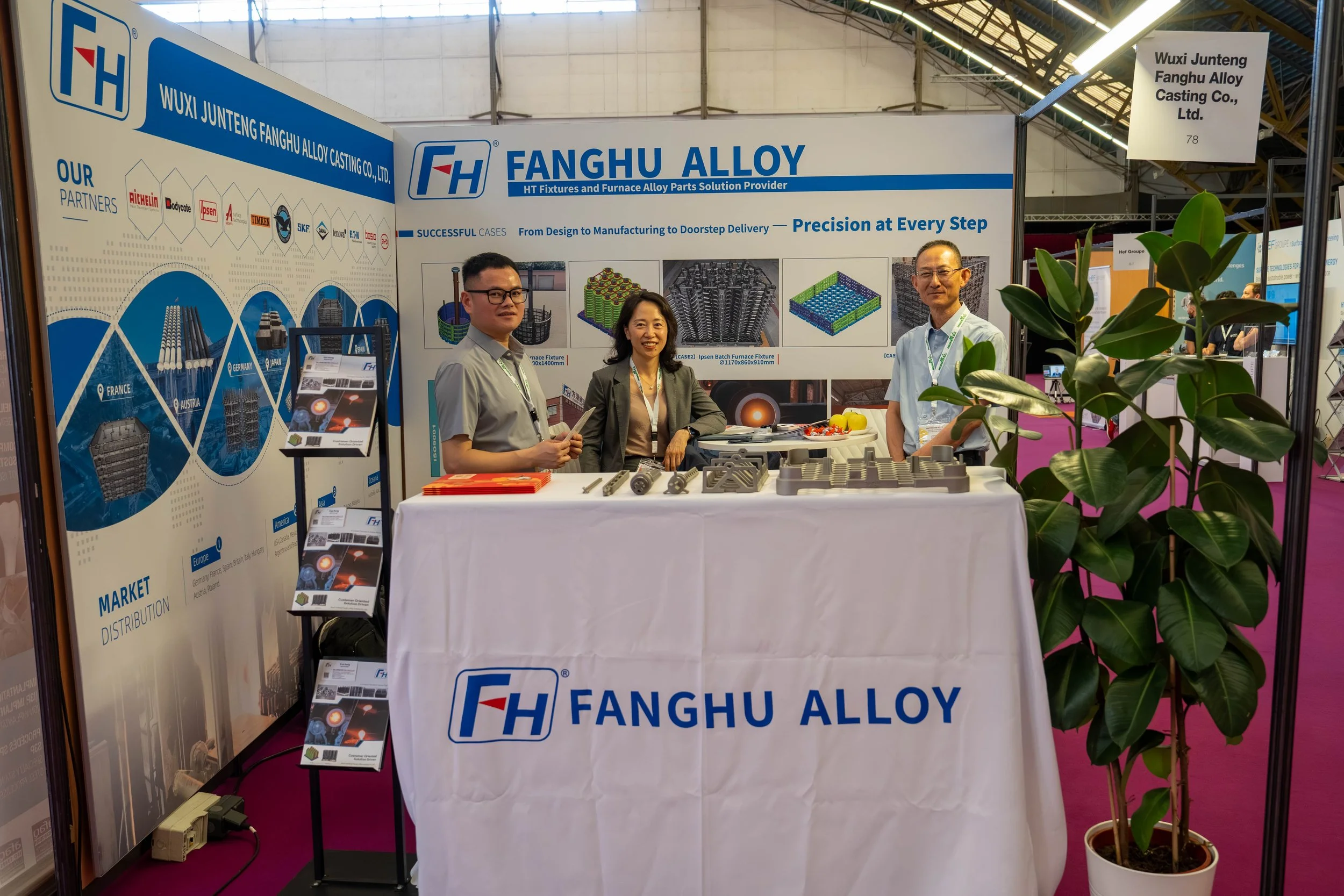

Meet the exhibitors at MATTRIS 2025

Organized in parallel with the conferences, the MATTRIS 2025 Show brought together 80 exhibitors to present their innovations, equipment and know-how. This exhibition space encouraged networking, the discovery of cutting-edge technological solutions and theemergence of collaborative ventures in the following areas:

Furnaces and heat treatment equipment

Surface treatment and coating

Measurement, control and regulation

Heat treatment and surface treatment processes and services

Specialty chemicals and consumables

Research, R&D, engineering and consulting

A highlight for industry professionals, marked by a wealth of exchanges and the quality of the contacts made.

Round table: Circular economy & recyclability of materials: what's at stake for heat and surface treatments?

On July 2, at the show, a groundbreaking round table brought together 4 speakers from different links in the value chain to discuss an increasingly strategic issue: 𝐥𝐞𝐬 𝐜𝐨𝐧𝐬𝐞́𝐪𝐮𝐞𝐧𝐜𝐞𝐬 𝐜𝐨𝐧𝐜𝐫𝐞̀𝐭𝐞𝐬 𝐝𝐞𝐬 𝐩𝐨𝐥𝐢𝐭𝐢𝐪𝐮𝐞𝐬 𝐝'𝐞́𝐜𝐨𝐧𝐨𝐦𝐢𝐞 𝐜𝐢𝐫𝐜𝐮𝐥𝐚𝐢𝐫𝐞 𝐬𝐮𝐫 𝐥𝐞𝐬 𝐟𝐢𝐥𝐢𝐞̀𝐫𝐞𝐬 𝐢𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐞𝐥𝐥𝐞𝐬 𝐭𝐫𝐚𝐢𝐭𝐚𝐧𝐭 𝐝𝐞𝐬 𝐦𝐚𝐭𝐞́𝐫𝐢𝐚𝐮𝐱.

🎙 Hosted by Etienne Bouyer - CEA (Direction des Programmes), the floor was given to :

💬 Discussions began with les𝐩𝐫𝐢𝐧𝐜𝐢𝐩𝐚𝐮𝐱 𝐦𝐨𝐭𝐞𝐮𝐫𝐬 𝐝𝐞 𝐥'𝐞́𝐜𝐨𝐧𝐨𝐦𝐢𝐞 𝐜𝐢𝐫𝐜𝐮𝐥𝐚𝐢𝐫𝐞: 𝐩𝐫𝐞𝐬𝐬𝐢𝐨𝐧 𝐫𝐞́𝐠𝐥𝐞𝐦𝐞𝐧𝐭𝐚𝐢𝐫𝐞, 𝐬𝐨𝐮𝐯𝐞𝐫𝐚𝐢𝐧𝐞𝐭𝐞́ 𝐬𝐭𝐫𝐚𝐭𝐞́𝐠𝐢𝐪𝐮𝐞, 𝐚𝐭𝐭𝐞𝐧𝐭𝐞𝐬 𝐑𝐒𝐄 𝐝𝐞𝐬 𝐝𝐨𝐧𝐧𝐞𝐮𝐫𝐬 𝐝'𝐨𝐫𝐝𝐫𝐞... Dynamics directly influencing suppliers and subcontractors.

🔹 𝐐𝐮𝐚𝐧𝐭𝐢𝐭𝐞́: Europe 𝐦𝐚𝐧𝐪𝐮𝐞 𝐝𝐞 𝐦𝐚𝐭𝐞́𝐫𝐢𝐚𝐮𝐱 𝐫𝐞𝐜𝐲𝐜𝐥𝐞́𝐬. Many vehicles, aircraft or scrap metals leave the continent at the end of their lives, depriving local industries of key resources to reduce their dependence on new metals. This scarcity 𝐜𝐨𝐦𝐩𝐥𝐢𝐪𝐮𝐞 𝐥𝐚 𝐦𝐨𝐧𝐭𝐞́𝐞 𝐞𝐧 𝐩𝐮𝐢𝐬𝐬𝐚𝐧𝐜𝐞 𝐝𝐞𝐬 𝐩𝐫𝐨𝐜𝐞́𝐝𝐞́𝐬 as the second electric smelting.

🔹 𝐐𝐮𝐚𝐥𝐢𝐭𝐞́: recycled metals present 𝐜𝐨𝐦𝐩𝐨𝐬𝐢𝐭𝐢𝐨𝐧𝐬 𝐯𝐚𝐫𝐢𝐚𝐛𝐥𝐞𝐬, requiring 𝐭𝐫𝐢 𝐫𝐢𝐠𝐨𝐮𝐫𝐞𝐮𝐱 𝐞𝐭 𝐚𝐝𝐚𝐩𝐭𝐚𝐭𝐢𝐨𝐧 𝐝𝐞𝐬 𝐩𝐫𝐨𝐜𝐞́𝐝𝐞́𝐬. These challenges can become opportunities, by integrating the circular economy right from the part design stage.

🔧 𝐀𝐮𝐭𝐫𝐞𝐬 𝐥𝐞𝐯𝐢𝐞𝐫𝐬 𝐞́𝐯𝐨𝐪𝐮𝐞́𝐬 : 𝐫𝐞́𝐩𝐚𝐫𝐚𝐛𝐢𝐥𝐢𝐭𝐞́, 𝐚𝐥𝐥𝐨𝐧𝐠𝐞𝐦𝐞𝐧𝐭 𝐝𝐞 𝐥𝐚 𝐝𝐮𝐫𝐞́𝐞 𝐝𝐞 𝐯𝐢𝐞, 𝐜𝐨𝐧𝐜𝐞𝐩𝐭𝐢𝐨𝐧 𝐩𝐨𝐮𝐫 𝐥𝐞 𝐝𝐞́𝐦𝐨𝐧𝐭𝐚𝐠𝐞, 𝐫𝐞𝐭𝐫𝐨𝐟𝐢𝐭 𝐝𝐞𝐬 𝐞́𝐪𝐮𝐢𝐩𝐞𝐦𝐞𝐧𝐭𝐬... For example, retrofitting industrial furnaces would reduce the use of new metal for a new installation by 50%.

💡 In conclusion, the speakers recalled that 𝐥'𝐞́𝐜𝐨𝐧𝐨𝐦𝐢𝐞 𝐜𝐢𝐫𝐜𝐮𝐥𝐚𝐢𝐫𝐞 𝐧𝐞 𝐩𝐞𝐮𝐭 𝐞̂𝐭𝐫𝐞 𝐝𝐢𝐬𝐬𝐨𝐜𝐢𝐞́𝐞 𝐝𝐞 𝐬𝐞𝐬 𝐫𝐞́𝐚𝐥𝐢𝐭𝐞́𝐬 𝐞́𝐜𝐨𝐧𝐨𝐦𝐢𝐪𝐮𝐞𝐬. Its success is based on a 𝐜𝐨𝐨𝐫𝐝𝐢𝐧𝐚𝐭𝐢𝐨𝐧 𝐝𝐞 𝐥'𝐞𝐧𝐬𝐞𝐦𝐛𝐥𝐞 𝐝𝐞 𝐥𝐚 𝐜𝐡𝐚𝐢̂𝐧𝐞 - producers, processors, recyclers - in a 𝐜𝐚𝐝𝐫𝐞 𝐫𝐞́𝐠𝐥𝐞𝐦𝐞𝐧𝐭𝐚𝐢𝐫𝐞 𝐚𝐝𝐚𝐩𝐭𝐞́ 𝐞𝐭 𝐜𝐨𝐡𝐞́𝐫𝐞𝐧𝐭.

🎥 The video of this round table will soon be available on our website

Materials for the Energy of the Future" roundtable discussion

🔋 𝐒𝐚𝐧𝐬 𝐦𝐚𝐭𝐞́𝐫𝐢𝐚𝐮𝐱 𝐚𝐝𝐚𝐩𝐭𝐞́𝐬, 𝐩𝐚𝐬 𝐝𝐞 𝐭𝐫𝐚𝐧𝐬𝐢𝐭𝐢𝐨𝐧 𝐞́𝐧𝐞𝐫𝐠𝐞́𝐭𝐢𝐪𝐮𝐞 𝐯𝐢𝐚𝐛𝐥𝐞.

This was the conclusion shared by the speakers at the round table held on July 3 as part of MATTRIS '25 by A3TS.

Whether it's a question of producing decarbonized energy, transporting it or consuming it more efficiently, materials and their processing are at the heart of all the technical and economic challenges we face.

🎙 Hosted by Pierre BRUCHETit brought together :

Hanlin Liao - Professor atBelfort-Montbéliard University of Technology

Daniel Lincot - Emeritus Research Director CNRSfounder of SOYPV

Jorge Arturo Soto Puente - Research engineer, Cetim - Centre technique des industries mécaniques

🌞 𝐏𝐡𝐨𝐭𝐨𝐯𝐨𝐥𝐭𝐚𝐢̈𝐪𝐮𝐞 - Daniel LINCOT emphasized the strategic importance of this sector, which is currently dominated by Asia. For Europe to regain the upper hand, we need 𝐚𝐦𝐞́𝐥𝐢𝐨𝐫𝐞𝐫 𝐥𝐞𝐬 𝐫𝐞𝐧𝐝𝐞𝐦𝐞𝐧𝐭𝐬 𝐞𝐭 𝐫𝐞́𝐝𝐮𝐢𝐫𝐞 𝐥𝐞𝐬 𝐜𝐨𝐮̂𝐭𝐬 𝐝𝐞 𝐩𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧, supported by 𝐭𝐫𝐚𝐢𝐭𝐞𝐦𝐞𝐧𝐭𝐬 𝐝𝐞 𝐬𝐮𝐫𝐟𝐚𝐜𝐞 𝐚𝐯𝐚𝐧𝐜𝐞́𝐬. A proactive industrial strategy and competence centers are essential to build a sovereign industry.

💧 𝐇𝐲𝐝𝐫𝐨𝐠𝐞̀𝐧𝐞 - Hanlin LIAO recalled the 𝐧𝐨𝐦𝐛𝐫𝐞𝐮𝐱 𝐝𝐞́𝐟𝐢𝐬 posed by this 𝐠𝐚𝐳 𝐢𝐧𝐬𝐭𝐚𝐛𝐥𝐞 𝐞𝐭 𝐝𝐢𝐟𝐟𝐢𝐜𝐢𝐥𝐞 𝐚̀ 𝐦𝐚𝐢̂𝐭𝐫𝐢𝐬𝐞𝐫. In 𝐞́𝐥𝐞𝐜𝐭𝐫𝐨𝐥𝐲𝐬𝐞𝐮𝐫𝐬, electrodes are a critical link: 𝐦𝐚𝐭𝐞́𝐫𝐢𝐚𝐮𝐱 𝐢𝐧𝐧𝐨𝐯𝐚𝐧𝐭𝐬, combined with processes such as 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐭𝐡𝐞𝐫𝐦𝐢𝐪𝐮𝐞 or 𝐞́𝐥𝐞𝐜𝐭𝐫𝐨𝐝𝐞́𝐩𝐨𝐬𝐢𝐭𝐢𝐨𝐧, make it possible to target 𝐩𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞, 𝐝𝐮𝐫𝐚𝐛𝐢𝐥𝐢𝐭𝐞́ 𝐞𝐭 𝐛𝐚𝐢𝐬𝐬𝐞 𝐝𝐞𝐬 𝐜𝐨𝐮̂𝐭𝐬.

🔬 𝐓𝐫𝐚𝐢𝐭𝐞𝐦𝐞𝐧𝐭𝐬 𝐝𝐞 𝐬𝐮𝐫𝐟𝐚𝐜𝐞 - Arturo SOTO detailed the requirements imposed by hydrogen on components: 𝐞́𝐭𝐚𝐧𝐜𝐡𝐞́𝐢𝐭𝐞́, 𝐫𝐞́𝐬𝐢𝐬𝐭𝐚𝐧𝐜𝐞 𝐚̀ 𝐥𝐚 𝐟𝐫𝐚𝐠𝐢𝐥𝐢𝐬𝐚𝐭𝐢𝐨𝐧, 𝐜𝐨𝐦𝐩𝐚𝐭𝐢𝐛𝐢𝐥𝐢𝐭𝐞́ 𝐜𝐡𝐢𝐦𝐢𝐪𝐮𝐞. Surface treatments are the key to the safety and longevity of the H₂ industry.

⚙️ 𝐒𝐨𝐛𝐫𝐢𝐞́𝐭𝐞́ 𝐞́𝐧𝐞𝐫𝐠𝐞́𝐭𝐢𝐪𝐮𝐞 - Bruno CAUWE recalled two powerful but often overlooked levers: the 𝐫𝐞́𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐝𝐞𝐬 𝐟𝐫𝐨𝐭𝐭𝐞𝐦𝐞𝐧𝐭𝐬 and the 𝐨𝐩𝐭𝐢𝐦𝐢𝐬𝐚𝐭𝐢𝐨𝐧 𝐝𝐢𝐦𝐞𝐧𝐬𝐢𝐨𝐧𝐧𝐞𝐥𝐥𝐞 𝐝𝐞𝐬 𝐬𝐲𝐬𝐭𝐞̀𝐦𝐞𝐬, to limit energy losses right from the design stage.

💡 This round table confirmed it: materials are not just a resource, they are a strategic lever for making a success of the energy transition.

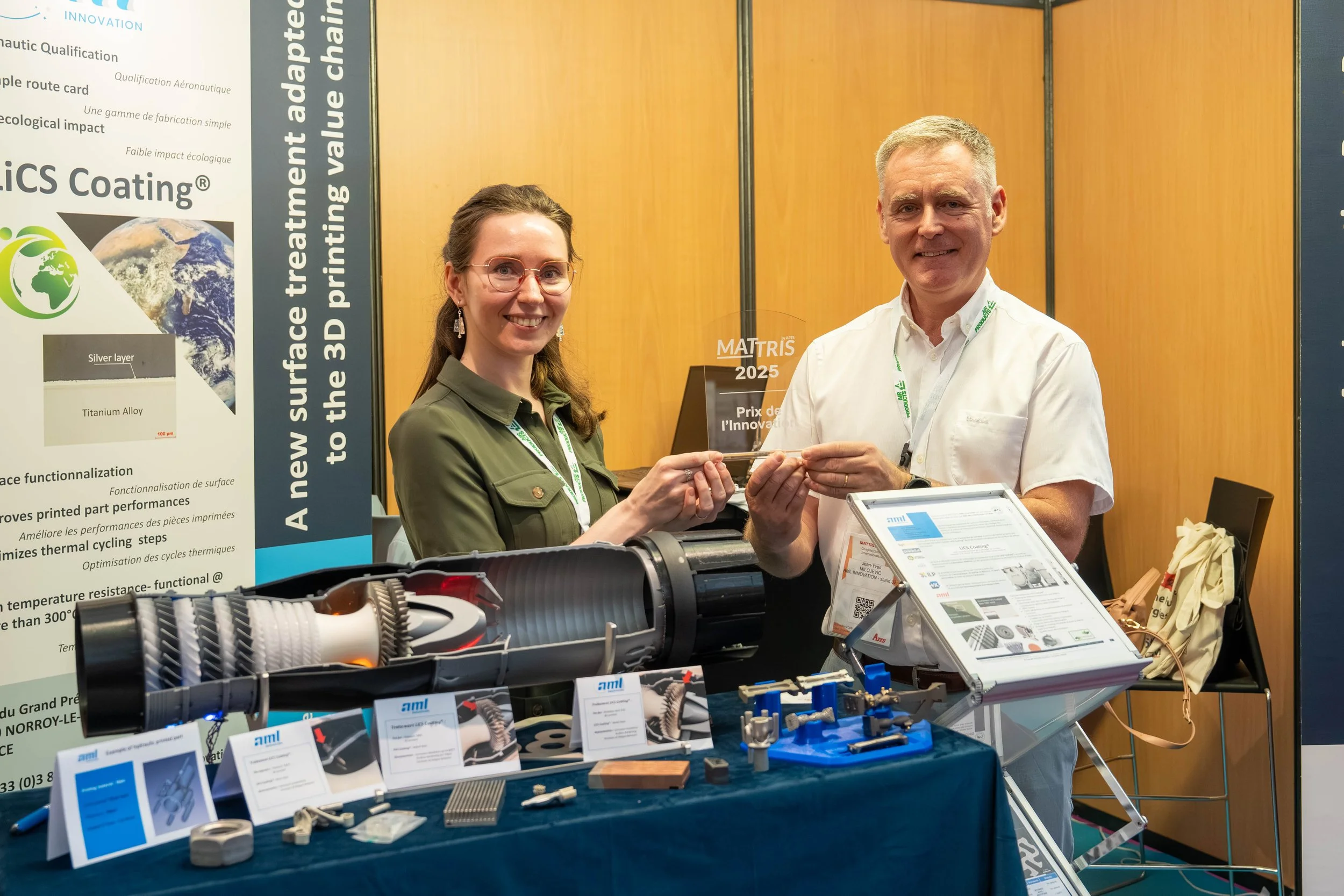

A3TS 2025 Innovation Award goes to AML Innovation for LiCS Coating®.

AML Innovation is an AML Group company located north of Metz dedicated to disruptive innovation in innovative surface treatments and multi-material vacuum brazing for the defense, aerospace and aeronautics markets. The company was founded in 2021 and received support from the French government's Economic Recovery Plan for the invention and development of a disruptive technology called LiCS Coating® (Liquid Chemical Suspension Coating), designed for metal deposits on machined and/or 3D-printed parts.

LiCS Coating® is a new coating and surface functionalization technology based on the use of a liquid suspension containing metal/metallic alloy powder. This coating adapts well to all shapes, sizes and types of metal/ceramic substrates, and is designed to be applied to internal channels with complex morphologies, or externally, selectively or not. The technology is REACh-compatible and uses no chemical baths.

-

LiCS Coating® is a new coating and surface functionalization technology based on the use of a liquid suspension containing metal/metallic alloy powder. This coating adapts well to all shapes, sizes and types of metal/ceramic substrates (machined, FabAdd...) and has been designed to be applied to internal channels with complex morphologies, or externally, selectively or not. The technology is REACh-compatible and uses no baths.

Question 1: In what context(s) is innovation envisaged?

LiCS Coating® technology was originally developed to solve a specific problem in the aerospace industry. To connect microwave transmitters and receivers to their antennas, in equipment such as radar, satellite communications and microwave radio links, waveguides are used to carry the waves between the various functions. They generally consist of a hollow metal tube with a conductive inner surface. Waveguides are usually made from materials such as aluminum, copper, stainless steel or titanium, with the inner surfaces electro-chemically plated with copper, silver or gold. However, as frequencies increased, waveguide channels narrowed to the point where traditional cladding methods became very difficult to use, if not inapplicable. It therefore became necessary to develop a technology for functionalizing complex internal channels, which led to the creation and implementation of LICS Coating®.

Question 2: What level of maturity has the innovation reached? What are the industrial references?

AML Innovation currently has a production line for metal parts treated with LiCS Coating ® technology. Since 2022, parts have been delivered to our customer in the defense and aerospace markets at a frequency of around one or two lines per month.

Question 3: Explain how innovation can contribute to the industrial performance of its user. What criteria can be used to measure its impact?

LiCS Coating ® can be applied to smooth machined surfaces, as well as to rough surfaces such as those used in foundries or 3D printingThe process has been designed to achieve surfaces or functionalize channels that are not possible with current technologies.The process combines an application step of a liquid suspension based on the alloy(s) to be deposited, and a heat treatment that melts said suspension to create the bond between the substrate and the coating. We do not use chemical baths to carry out our treatments, so several operations can be carried out at the same time (under certain conditions):

Surface functionalization

Smoothing surfaces

Improved mechanical properties (fatigue life)

Trapping detachable particles in the coating

High mechanical and thermal resistance of the coating

Penetration of the substrate to fill porosities or cracks

Brazing

And heat treatment

We therefore believe that LiCS Coating® contributes to industrial performance by pooling certain operations and thus reconsidering conventional industrial schemes. LiCS Coating® also represents a real breakthrough in technology, particularly in the 3D world, enabling us to push back the limits of parts and products made by additive manufacturing. The impact can be measured in terms of cost, alternative solutions, ecological impact, or simply feasibility.

Question 4: Explain the technological content of the innovation. What were the technical challenges? What are the competing solutions/technologies?

LiCS Coating® technology is an innovative surface coating and/or functionalization method based on the use of a suspension. Typically, the suspension contains metal powder (pure metal or alloys) and a liquid binder. The composition of the suspension can be modified and adapted to specific needs, which is one of the main advantages of the invention. Another advantage is that, thanks to its liquid form, this innovation is suitable for metal/ceramic parts of any geometry, with simple or complex internal cavities, for complete or selective surface coating.

And last but not least, LiCS Coating® offers a relatively simple and inherently environmentally-friendly range, compared with other processes. Solutions/technologies such as vapor deposition, galvanizing, wet chemical deposition, conversion coatings (spraying or dipping) and thermal spraying can be considered as competing technologies.

The present invention claims a technological breakthrough with respect to these solutions and in particular thanks to the following points:

The quality of the coating (homogeneous, even and non-porous);

Adjustable, even coating thickness;

The size of the coated channels (currently 0.8mm in diameter)

Mechanical and thermal resistance of the coating; the surface can be reworked (e.g. mechanical polishing or machining);

Gives the surface a function (cosmetic or technical: conductive, surface hardness enhancement, anti-corrosion protection, etc.);

The solution is suitable for parts of all geometries, with or without simple or complex internal cavities, for full or selective surface coating.

Question 5: Does innovation contribute to improving the environmental impact of the industrial user?

The innovation presented is an eco-responsible process that complies with REACh requirements. In addition, other important indicators of the environmental friendliness of the process can be added:

Use the right amount of suspension for the surface to be covered;

No chemistry, compared to electroless or electrolytic deposition processes;

Few rejects ;

No chemical waste to reprocess;

No bath to maintain - no chemistry except surface preparation if necessary;

Certain types of powder used for innovation can be collected, recycled and reused.

Contact: Jean-Yves MILOJEVIC and Daria Zhemchuzhnikova PhD

jeanyves.milojevic@aml-microtec.com

daria.zhemchuzhnikova@aml-microtec.com

Four other innovations competed for this award:

-

The intelligent gas analyzer integrated into Air Products' Smart Technologies platform is modular in design. The components required to monitor and control a specific heat treatment process are selected and configured accordingly. The smart analyzer itself includes up to 7 selectable atmosphere sensors, a software package required for the specific process, process data acquisition and upload to the cloud-based platform for visualization, documentation and data extraction. Data acquisition is scalable to include material and quality data, and can be linked to a customer data network such as a Scada system or PLC to provide extensive data retrieval such as trend identification and process correlations that help analyze and provide feedback for process improvement.

Question 1: In what context(s) is innovation envisaged?

The main aim of innovation is to provide customers with greater efficiency in the use of resources to produce little or no waste, improve productivity with little or no rework, reduce production costs and thus reduce the carbon footprint of production.

Question 2: How mature is the innovation? What are the industrial references?

The solution is currently installed at three customer sites in Germany, one of which is part of a consortium sponsored by the German government, the HydroConnect project.

Question 3: Explain how innovation can contribute to the industrial performance of its user. What criteria can be used to measure its impact?

Air Products' smart gas analyzer and Smart Technologies services enable optimization of heat treatment processes, process control options and local monitoring, while data collected in the cloud can be used to examine process deviations, identify links between process values, assess part quality and enable optimal process settings rather than following fixed parameters and an empirical approach to process execution.

Data acquisition is scalable to include material and quality data, and can be linked to a customer data network such as a Scada system or PLC to provide extensive data extraction such as trend identification and process correlations that help analyze and provide feedback for process improvement.

Question 4: Explain the technological content of the innovation. What were the technical challenges? What are the competing solutions/technologies?

Monitoring and control of the heat treatment process, as well as data acquisition and documentation, are familiar to the industry and largely covered by the system. The innovation lies in the reception of data and the return of analytical results to the process, which involves the implementation of machine learning algorithms, the provision of consultative information to improve the process and the prediction of quality, productivity such as furnace loading, and the right to preventive maintenance.

Question 5: Does innovation contribute to improving the environmental impact of the industrial user?

This solution is advantageous for the customer, as it ensures transparency, traceability and documentation of the process, enabling it to be optimized.

The main benefits for the customer are greater efficiency in the use of resources, as little or no waste is produced; increased productivity, as little or no rework is required; lower production costs, and therefore a reduction in the carbon footprint of production.

-

Modular, cold-wall nitriding and carbonitriding cell, with metal heating element (eliminates HCN risk), operating pressure from primary vacuum to PA, a system which is currently being manufactured and will be installed at our test centers in Grenoble and the USA. This new cell completes the versatility of our ICBP, and is available in sizes 966, 1T, or 1299, 2T.

Question 1: In what context(s) is innovation envisaged?

This innovation stems from the industrial need to be able to control the carbonitriding phases at low pressure, in order to reduce utility consumption and CO2 emissions. The idea is to carry out the carburizing phases at high temperature 940-980 in a cell, and transfer to a lower-temperature cell to carry out the carbonitriding phase.

Question 2: What level of maturity has the innovation reached? What are the industrial references?

The core system, the ICBP, has been mastered and deployed worldwide for over 30 years. There are two limitations to using the two phases in sequence at the same temperature: 1) NH3 recombines too rapidly at high temperature, resulting in poor process homogeneity. 2) The generation of HCN by contact of NH3 with graphite elements. The first point has been resolved through trials with automotive industry customers (European and Chinese), i.e. carrying out the carburizing and carbonitriding phases in different chambers at different temperatures, with vacuum transfer. The remaining problem to be solved is HCN generation. The new cell uses metallic heating elements. It has been patented and is currently being manufactured, and will be installed at our test centers in Grenoble and the USA by the end of the year.

Question 3: Explain how innovation can contribute to the industrial performance of its user. What criteria can be used to measure its impact?

It eliminates the HCN risk thanks to its graphite-free design.

Production costs are reduced by using a cold-wall furnace rather than a muffle furnace.

Finally, we'll find all the economic advantages of a modular plant: reduced consumption thanks to cooling in a separate chamber, but also thanks to the fact that we can play with a process pressure ranging from primary vacuum to PA (following vacuum purging).

Question 4: Explain the technological content of the innovation. What were the technical challenges? What are the competing solutions/technologies?

Multi-process cell for nitriding with post-ox, and carbonitriding phases. De facto, a cell capable of working with precision +/-5°C from 400°C to 900°C, and from primary vacuum to PA, integrating the following process utilities: NH3,N20,CO2,Air,Water

To our knowledge, our multi-chamber furnace competitors have not yet come up with a solution. ALD's conclusions (cf. A3TS conference in Toulouse) are the same as ours when all phases are carried out in the same graphite furnace: homogeneity of treatment over 1/4 of the charge, and generation of HCN.

Question 5: Does innovation contribute to improving the environmental impact of the industrial user?

The aim of this innovation is to eventually eliminate the need for atmospheric carbonitriding gas furnaces, thereby significantly reducing CO2 emissions.

-

Is it possible to save up to 80% gas and achieve better results at the same time? -YES, IT IS - with Ipsen GreenFlow.

The intelligent system dynamically reduces gas supply in real time - adapted to your processes and production conditions.

After loading, GreenFlow precisely measures the furnace atmosphere - and automatically adjusts the gas supply. The system reacts in real time to door movements or atmospheric changes and keeps the protective gas atmosphere constant - more efficiently than any conventional control system.

Question 1: In what context(s) is innovation envisaged?

Increasing the energy efficiency of heat treatment: The aim of the GreenFlow gasification system is to save process media and heating energy in order to make atmospheric carburising and (case) hardening processes as energy-efficient as possible. Due to the high savings in process media and heating energy (regardless of whether this is achieved through gas burners or electric heating), CO2 emissions are also drastically reduced.

Question 2: How mature is the innovation? What are the industrial references?

The GreenFlow heating system was developed and tested on furnaces at the Ipsen FutureLab.Several systems (the first one for 1.5 years) are currently in use at customer sites and are being used for production.Both systems with endogas or nitrogen/methanol heating are in use.

Question 3: Explain how innovation can contribute to the industrial performance of its user. What criteria can be used to measure its impact?

The GreenFlow heating system enables users/customers to save up to 80% of the process media previously used (while maintaining the same quality of heat treatment results).This leads to more energy-efficient and therefore more cost-effective heat treatments, giving users a price advantage over their competitors. In addition to the above-mentioned reduction in resource consumption, CO2 emissions are also reduced, which significantly improves the CO2 footprint of the heat treatment process (again an advantage over the competition).

Question 4: Explain the technological content of the innovation. What were the technical challenges? What are the competing solutions/technologies?

High-precision monitoring of the furnace atmosphere with the GreenFlow gas supply system makes it possible to use only as much process gas for heat treatment as is necessary to achieve the desired heat treatment results. (Previously, too much gas was always used to compensate for fluctuations/irregularities in the furnace atmosphere).

The biggest challenge was developing suitable (gas) analysers and control concepts to ensure a uniform furnace atmosphere (while complying with all safety requirements).As far as we know, there is currently no comparable market-ready competitor product, which makes the GreenFlow gas supply system a unique selling point for Ipsen.

To our knowledge, there is currently no comparable market-ready competitive product, which makes the GreenFlow gas supply system a unique selling point (USP) for Ipsen.The GreenFlow system is a unique solution for the specific requirements of Ipsen.

Question 5: Does innovation contribute to improving the environmental impact of the industrial user?

Yes, by drastically reducing the process media used (e.g. natural gas, methanol and nitrogen) as well as reducing the heating energy required (natural gas or electrical energy) and thus also drastically reducing CO2 emissions.

-

For decades, hardening depth has been verified by sampling and destructive testing, which is time-consuming and costly: sawing, coating, polishing, hardness filiation.

By implementing a Deep Learning AI overlay to its multi-frequency, multi-harmonic eddy current control technology, ibg can non-destructively predict the hardening depth on cylindrical parts with an accuracy of +/-75 μm.

Question 1: In what context(s) is innovation envisaged?

This innovation can be integrated downstream of induction heat treatment in medium or large production runs. It can be deployed both in the metallurgical laboratory and on automated lines for 100% control.

Question 2: How mature is the innovation? What are the industrial references?

One industrial application has been in operation for over a year. 2 are currently being implemented.

Question 3: Explain how innovation can contribute to the industrial performance of its user. What criteria can be used to measure its impact?

Performance improvement is threefold.

1- improved quality/safety through better detection of non-conforming parts

2- reduced inspection costs: no consumables with eddy currents, no destruction of parts, reduced labor time.

3- time savings: control is instantaneous (a few seconds) and production no longer has to wait several tens of minutes for laboratory results.

Question 4: Explain the technological content of the innovation. What were the technical challenges? What are the competing solutions/technologies?

Prior to this innovation, ibg's eddy current testing was very efficient, thanks to the simultaneous use of 8 frequencies and 2 harmonic levels. Each component was evaluated by 24 pairs of X,Y coordinates in the impedance plane.

This is more than enough to detect any metallurgical heterogeneity (differences in microstructure or chemical composition).

The challenge was to process this data to predict a hardening depth expressed in mm, and not just a good/bad sanction.

We have compiled a wealth of cross-referenced hardness measurement (destructive) and CF (non-destructive) data. In parallel, we developed an adapted AI model based on Deep Learning (Convolutional Neural Networks - CNN).

The model thus developed is generic for induction-treated cylindrical components. These include CV joint spindles, transmission shafts, cylinder rods...

Question 5: Does innovation contribute to improving the environmental impact of the industrial user?

Yes, by significantly reducing the number of components destroyed for analysis, the environmental impact on the industry is reduced.

What's more, better control of induction hardening depth means that less electrical energy is used for induction. Even if the reduction is modest in %age, this is one of the most important consumption items, and the final gains are substantial.

A3TS 2025 Thesis Awards

Scientific excellence in the spotlight: 2025 Thesis Awards Ceremony

The highlight of this year's event in Dijon, the A3TS Thesis Awards ceremony, took place on Thursday, July 3, at the MATTRIS 2025 trade show. This year, the jury recognized two research projects that perfectly illustrate the synergy between laboratories and industry. In the Heat Treatment category, the prize was awarded to Victor Pacorel (Institut Carnot-de Bourgogne, Dijon) for his work on the high-temperature oxidation of titanium alloys, providing crucial answers for the lightweighting of aeronautical structures. In the Surface Treatment category, Julymar Rodriguez (UTINAM Institute, Besançon) was awarded for her innovative study on the electropolishing of gold alloys. By proposing the use of deep eutectic solvents, she is paving the way for safer and more environmentally friendly finishing processes for the luxury goods industry. These awards confirm the A3TS's leading role in promoting cutting-edge technological research.

Doctoral students who have defended or will defend their doctoral theses in these two disciplines before the end of 2025, take note! The call for applications for the 2026 thesis awards, which will be presented at the MATTRIS 2026 trade show in Dunkirk, will open in January... Spread the word...

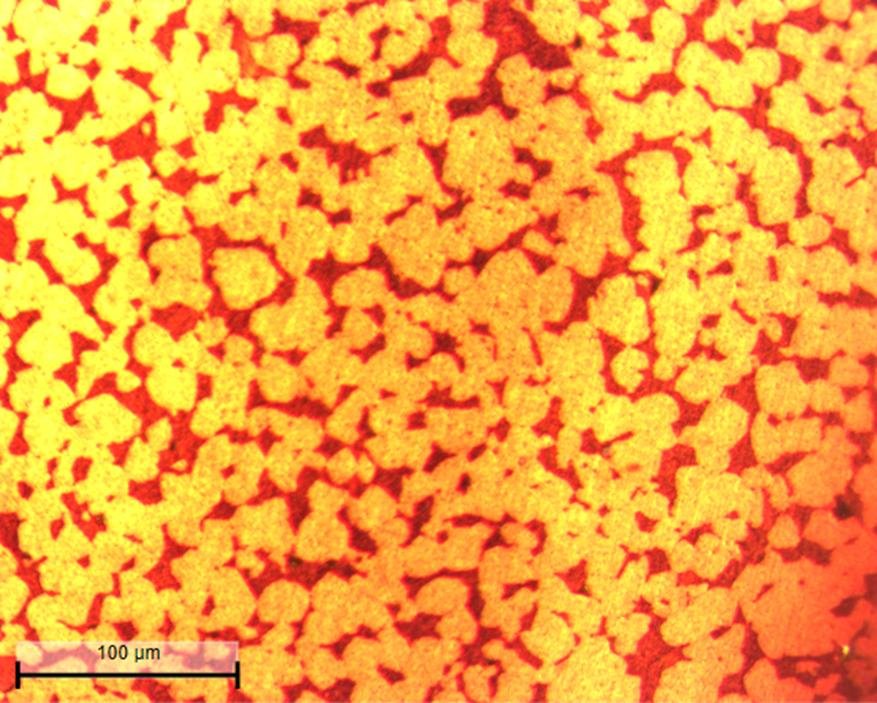

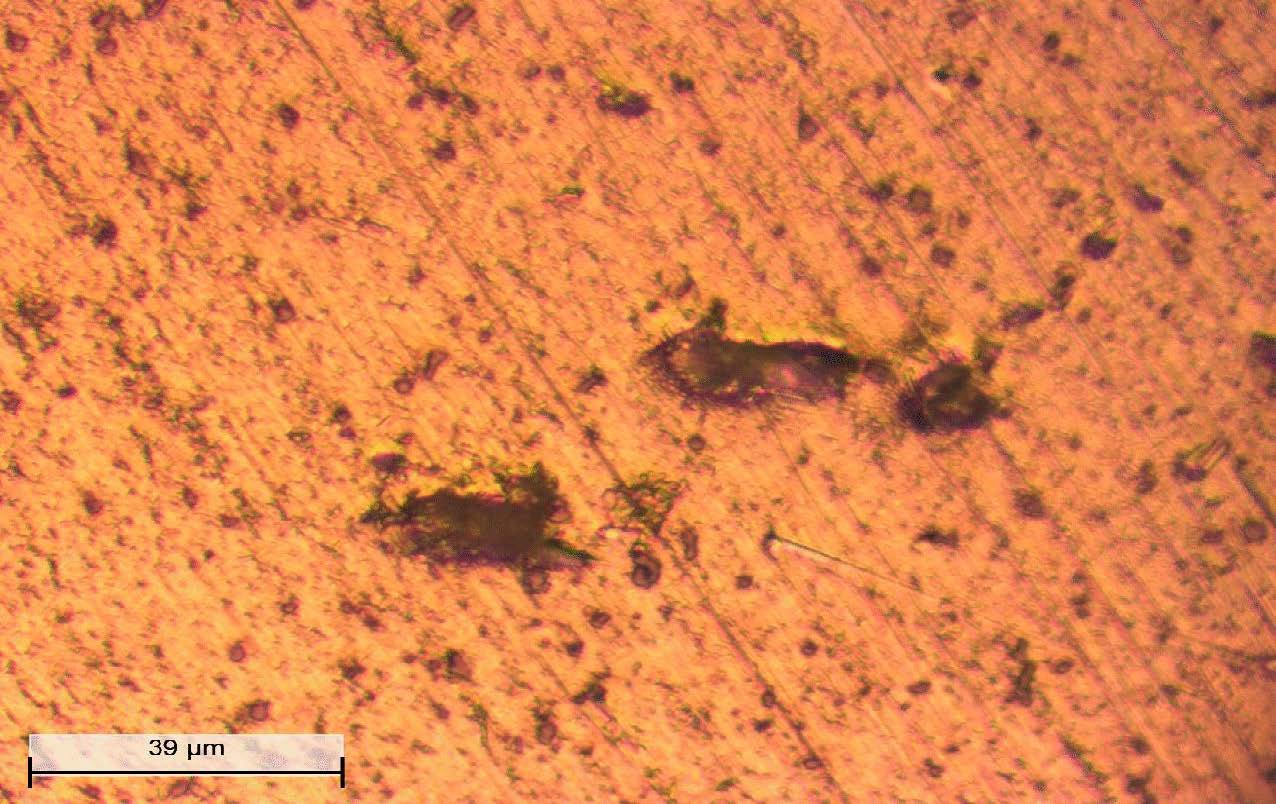

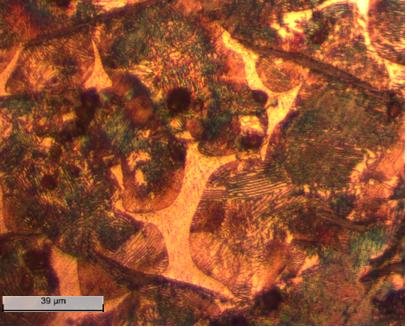

A3TS 2025 photo competition

🏆 First Prize

A3TS 2025 Photo Competition: the winners in the spotlight

As part of the MATTRIS 2025 conference, the A3TS photo competition was held on the theme of "Materials processing under the microscope". Organized by a team made up of members from A3TS, education and industry, the competition once again highlighted the technical expertise, creativity and communication skills of the participants.

The jury, made up of representatives from A3TS, LAM Plan, Oerlikon, Bodycote and academia, awarded the following prizes:

🏆 F irst Prize: A starry night - Pauline Mougeot, UFR Sciences et Techniques - Besançon

🔧 Prix de la technicité: Cementite in granite? - Jean Stemmelen, Lycée Jean Mermoz - Saint-Louis

🎨 Prize for originality: Origami in silver metal around a lake - Théo BERTHUIT, Lycée Théophile Roussel - Saint-Chély d'Apcher

📢 Paper prize: Post-volcanic landscape and carbide rivers - Chems-edine ZOUAIMIA, Lycée Jean Mermoz - Saint-Louis

Each prize was rewarded with vouchers for laboratory preparation products, donated by A3TS and LAM Plan.

Congratulations to all the winners! See you next year in Dunkirk for another edition of the competition!

Many thanks to our partner LAM PLAN for its involvement and contribution to this event.

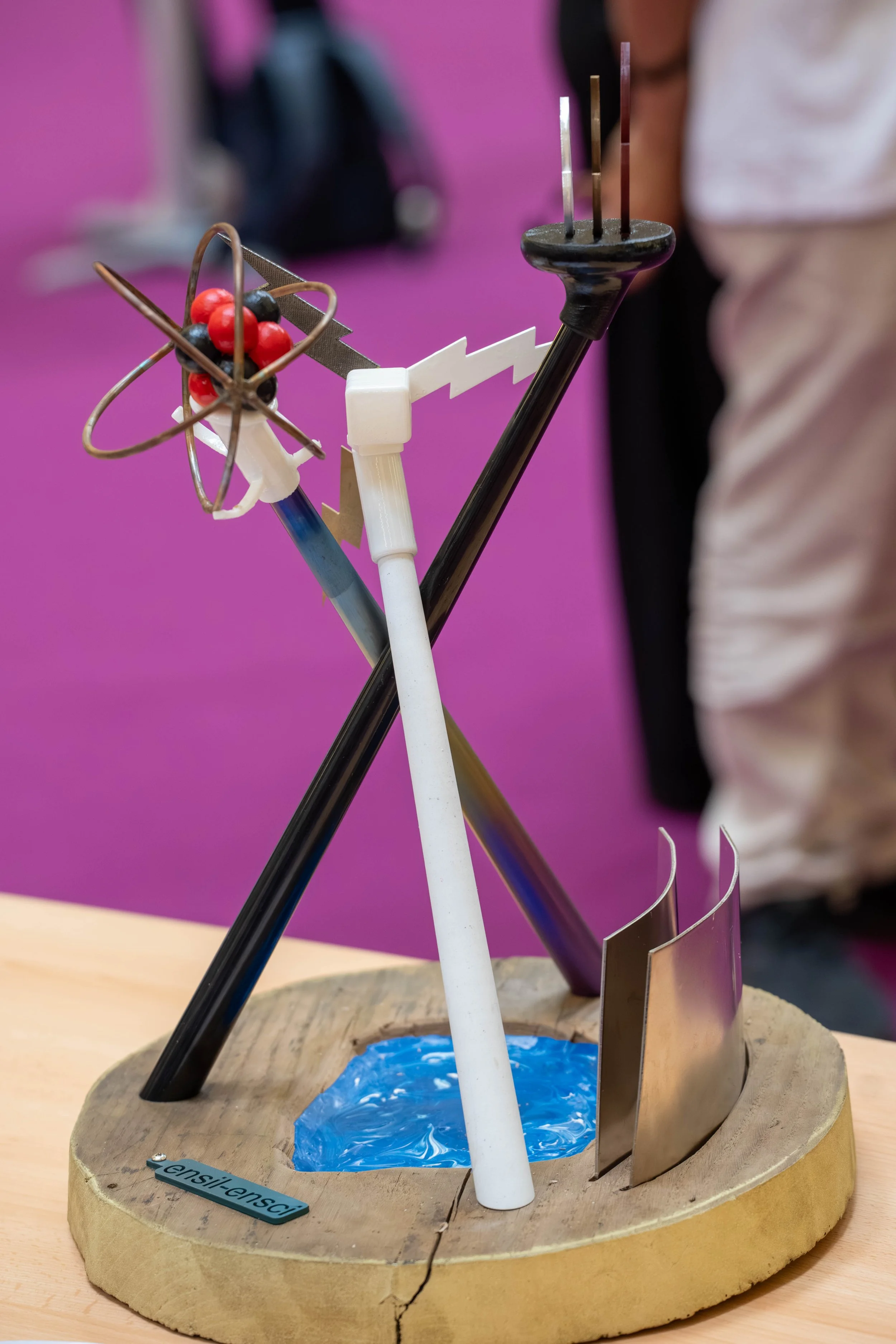

The UITS 2025 Youth Trophies:

On July 3, the UITS Jeunes Étudiants 2025 awards were presented.

This year's central theme was the energy sector, with its various surface treatment and heat treatment processes.

Participants had to demonstrate creativity, team spirit and innovation, using the full range of materials processing techniques.

Congratulations to the winners for their commitment and their superb creations!

IUT Besançon-Vesoul - Winner of the Innovation Award

IUT Besançon-Vesoul - Coup de cœur du jury

ENSIL-ENSCI (Limoges) - Winner of the Technicity Award

Master FTS - Formulation et Traitement des Surfaces (Besançon ) - Winner of the Aesthetics Award AND the 1st Prize of the 2025 Edition

📅 See you in 2027 for the next edition of the UITS trophies!

Job Dating

On Thursday morning, July 3, job dating took place at the show. Numerous candidates were able to meet the exhibitors present.

All the players and companies had meetings with quality candidates, enabling them to consider recruitment and potential collaborators.

Find all job offers still available here :

https://www.a3ts.org/offres-demploi

An exceptional evening at Château de Marsannay

On July 3, the MATTRIS '25 by A3TS gala evening brought together 250 participants in the heart of Burgundy, at the prestigious Château de Marsannay, emblem of the Cité du Vin et de la Gastronomie.

In a convivial atmosphere, guests were able to discover the surrounding vineyards and taste four of the estate's great wines.

After a cocktail reception and a stroll through the château's cellars, dinner was held in a magnificent vaulted cellar. The evening was punctuated by the intervention of a mentalist magician, whose bluffing tricks amazed the assembly.